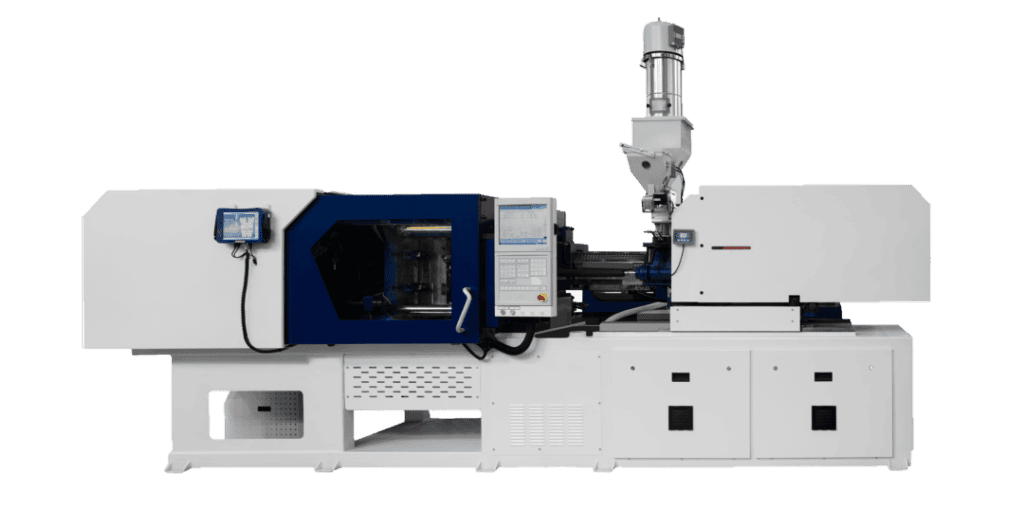

PLASTIC INJECTION

In a meticulously controlled process, molten plastic materials are stirred by a screw, injected into the mold cavity at high pressure, and then cooled and cured to obtain a molded product. This method is particularly well-suited for the large-scale production of complex-shaped components and is regarded as one of the most significant processing methodologies.

Here at Novelsan, we specialize in delivering high-quality plastic injection molding solutions that transform your concepts into durable, high-performance products. Our expertise lies in creating complex, intricate designs with tight tolerances, ensuring that each part meets your exact specifications. With a focus on material versatility, precision, and efficiency, our plastic injection molding solutions are designed to maximize both performance and value.

We are dedicated to providing you with solutions that drive your business forward, with a commitment to quality and customer satisfaction at every stage of production.