ROTATIONAL MOLDING

Rotational molding, also referred to as rotomolding, is a plastics molding technology that is particularly well-suited for the production of hollow articles. Unlike most other plastics processes, it does not involve pressure. This method is cost-effective due to the fact that moulds do not need to withstand pressure, enabling economical production runs to be achieved.

Rotomolding is a highly versatile process, with applications ranging from the production of household items to industrial components. The process offers product designers exceptional freedom, allowing for the production of virtually any shape. The process’s versatility extends to its capacity for molding items of virtually any size, making it a highly adaptable manufacturing method with thousands of potential applications. With the ability to use a wide range of materials and provide excellent flexibility in design, rotational molding solution is the perfect solution for creating long-lasting, high-quality products that are both cost-efficient and environmentally friendly.

Here at Novelsan, we are dedicated to collaborating with our clients to deliver customized solutions that align with their specific requirements and provide optimal products for their specific applications.

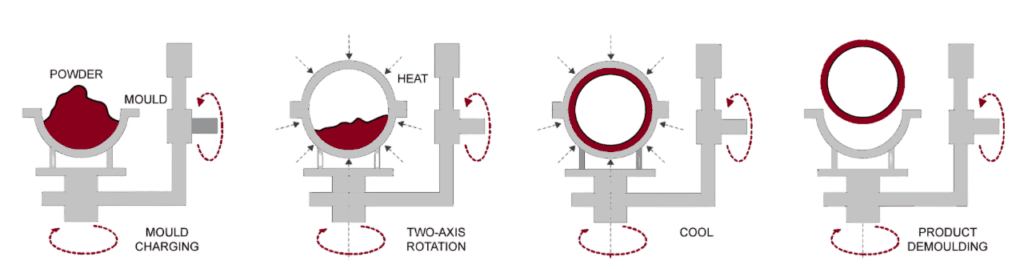

ROTATIONAL MOLDING MADE SIMPLE

Rotational molding involves the addition of plastic powder or liquid resin to a hollow mold, which is then rotated bi-axially in an oven until the material melts and coats the inside of the mold cavity. The tool is then left to cool and the plastic is allowed to solidify. The plastic component is removed from the tool, resulting in the creation of the finished part.